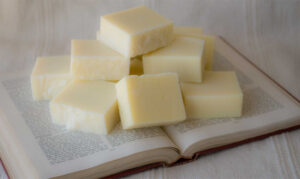

Encountering a white, powdery film on your lovingly crafted soap bars? You’re likely witnessing soda ash on soap, a common yet harmless occurrence in cold process soap making. While some appreciate this rustic patina as a hallmark of handcrafted soap, others strive for a pristine finish.

Whether you love the rustic charm of soda ash on soap or prefer smooth, vibrant bars, this guide will help you understand and control this soap-making artifact.

This guide delves into the nature of soda ash on soap, its potential causes, and effective strategies for prevention and removal, helping you achieve the perfect bar every time.

We will explore:

- What soda ash is (and what it isn’t)

- Why soda ash forms on cold-process soap

- How to prevent this white veneer with pro tips

- Best ways to remove it for a flawless finish

What Exactly is Soda Ash on Soap?

Is Soda Ash the Same as Lye?

No! Soda ash is not the same as excess lye (sodium hydroxide). Excess lye makes soap harsh and unsafe, whereas soda ash is purely cosmetic. Always rule out lye heavy soap, however, before assuming it’s just soda ash.

In the world of soap making, “soda ash” describes that light-colored or white, chalky layer that can appear on the surface of cold process soap. Despite its name, this residue isn’t necessarily a true soda ash or sodium carbonate (washing soda). Soap makers theorize it’s often a blend of true soda ash, other soap crystals, and potentially other salts.

While harmless to the skin, soda ash on soap can detract from the visual appeal of your bars, potentially making it less desirable for sale. Understanding its formation is the first step towards managing it effectively.

Theories Behind Soda Ash Formation on Soap

Several factors contribute to the development of soda ash on your precious soap bars:

- Soap Crystallization

As Susan Miller Cavitch proposed in The Soap Maker’s Companion, the glycerin, a natural byproduct of soap making, attracts moisture from the air. This moisture can dissolve surface soap particles. Upon evaporation, these dissolved particles recrystallize, forming the chalky layer. - True Soda Ash Formation

Some soapmakers believe that a small amount of sodium from the lye reacts with carbon dioxide in the air during saponification or curing, forming true sodium carbonate (soda ash) that settles on the soap’s surface. However, this explanation is unlikely. If this reaction were the main cause, soda ash would form every time we make soap — yet it only happens occasionally. While lye does always react with carbon dioxide in the air, the amount involved is too small to produce significant deposits of soda ash or baking soda on its own. - Formation of Other Salts

Similar to sodium carbonate, other salts like sodium bicarbonate or sodium chloride can form during saponification. Impurities and minerals present in both the oils and the water can react with the sodium hydroxide (lye) to create these various salt compounds. - Water Evaporation and Salt Migration

Excess water in your soap recipe acts as a solvent. As this water evaporates during curing, it can carry dissolved salts towards the soap’s surface. Upon evaporation, these salts are left behind as the visible ash.

Why does Soda Ash Form on Cold Process Soap? Key Factors

Several conditions can increase the likelihood of soda ash formation on your soap:

Soap Recipe and Ingredients

- Excess Water in Soap Recipe

Higher water content facilitates the movement of dissolved salts to the surface during the curing process. - High Lye Discount/Superfat Level

Counterintuitively, a higher superfat level can lead to more unsaponified oils containing minerals that react with lye, forming salts that contribute to soda ash veneer. - Oil Composition

Different oils and their combinations can influence the mechanisms of soda ash formation.

Processing and Environmental Factors

- Low Oil Temperature

If oils are too cool when lye is added, incomplete saponification can occur, potentially leading to more salt formation. - Thin Trace

Soap poured at a thin trace indicates incomplete saponification, leaving more free lye to react with other elements and resulting in lower soap density. - Low Soap Density

Less dense soap allows for easier migration of salt-laden water to the surface. Certain fragrance and essential oils can also decrease soap density. - Cold and Humid Environment

- Moisture Condensation

High humidity and low temperatures can cause moisture to condense on the curing soap, dissolving surface soap and leading to recrystallization. - Salt Migration

In humid conditions, salt-carrying moisture reaches the surface before evaporating, depositing the salts.

- Moisture Condensation

- Rapid Cooling

Soap cooling too quickly can also lead to moisture condensation on the surface, promoting soap crystal formation.

Strategies to Prevent Soda Ash on Soap

Proactive measures can significantly reduce or eliminate soda ash on homemade soap:

- Spritz with Rubbing Alcohol

After pouring into molds, at the first sign of gel phase, and after unmolding, lightly spray the soap surface with isopropyl alcohol. This helps to dry any surface moisture. - Use Distilled or Rainwater

Minimize mineral content by using distilled or rainwater instead of tap or well water. - Insulate Soap

Ensure slow and even cooling by insulating your molds. - Cover Soap

Covering the mold with plastic wrap can limit air exposure (use caution with milk soaps due to potential overheating). - Achieve Thick Trace

Ensure your soap batter reaches a medium to thick trace before pouring to promote complete saponification and increase density. - Incorporate Beeswax

Adding 1-3% beeswax (based on total oil weight) can increase soap density, trapping salts within the bar. - Use a Dehumidifier

Reduce air humidity in your curing environment. - Mix at Lower Temperatures

Combining lye and oils at slightly lower temperatures can help control the saponification process.

Effective Methods for Removing Soda Ash

If soda ash does appear, don’t despair! Several simple techniques can restore your soap’s smooth appearance:

- Water Dip

Briefly dip each soap bar in cold water and allow it to air dry. Wear gloves to prevent fingerprints. - Nylon Scrub

Gently buff the soda ash away using old nylon stockings. - Alcohol Spritz

Lightly spray the affected surface with 91% isopropyl alcohol and let it dry naturally (no scrubbing needed). - Glycerin Application

Brush a thin layer of glycerin onto the soap surface and let it dry. - Steaming

- Hold soap bars over steam from a pot or kettle.

- Use a clothes steamer or steaming iron.

- For larger batches, place soap in a sealed plastic tub with a glass of boiling water, replenishing the hot water as needed.

- Gentle Scraping (Planing)

Carefully scrape off the ash using a knife or vegetable peeler.

Final Thoughts: Embrace or Eliminate?

Some soap makers love soda ash on soap for its rustic, vintage appeal. Others remove it for a polished, professional look. Now that you know the causes and fixes, you can decide what works best for your soap!

Key Takeaways

- Soda ash is harmless but can be minimized.

- Thicker trace, less water, and controlled temps help prevent it.

- Steaming, alcohol, or light scrubbing easily removes soap ash.

By understanding the science behind soda ash on soap and implementing these preventive and removal techniques, you can consistently create beautiful, ash-free handcrafted soap that will delight both you, your family, and your customers. Embrace the art of soap making, and let your vibrant creations shine!

FAQ About Soda Ash on Soap

Q: Does soda ash mean my soap is lye-heavy?

A: No! Soda ash is cosmetic, while lye heaviness makes soap harsh. Test with a pH strip (safe soap is pH 8–10).

Q: Can I rebatch soap to remove soda ash?

A: Yes, but it’s time-consuming. Steaming or rinsing is faster.

Q: Does hot process soap get soda ash?

A: Rarely! The cooked method reduces ash risk.

Q: Will soda ash affect lather?

A: Nope—it’s purely visual.

Want more soap-making tips? Check out our [Ultimate Cold-Process Soap Guide] or [How to Fix Soap Making Mistakes].

By optimizing your technique, you can control soda ash on soap and create stunning, professional-quality soap every time!