Your cart is currently empty!

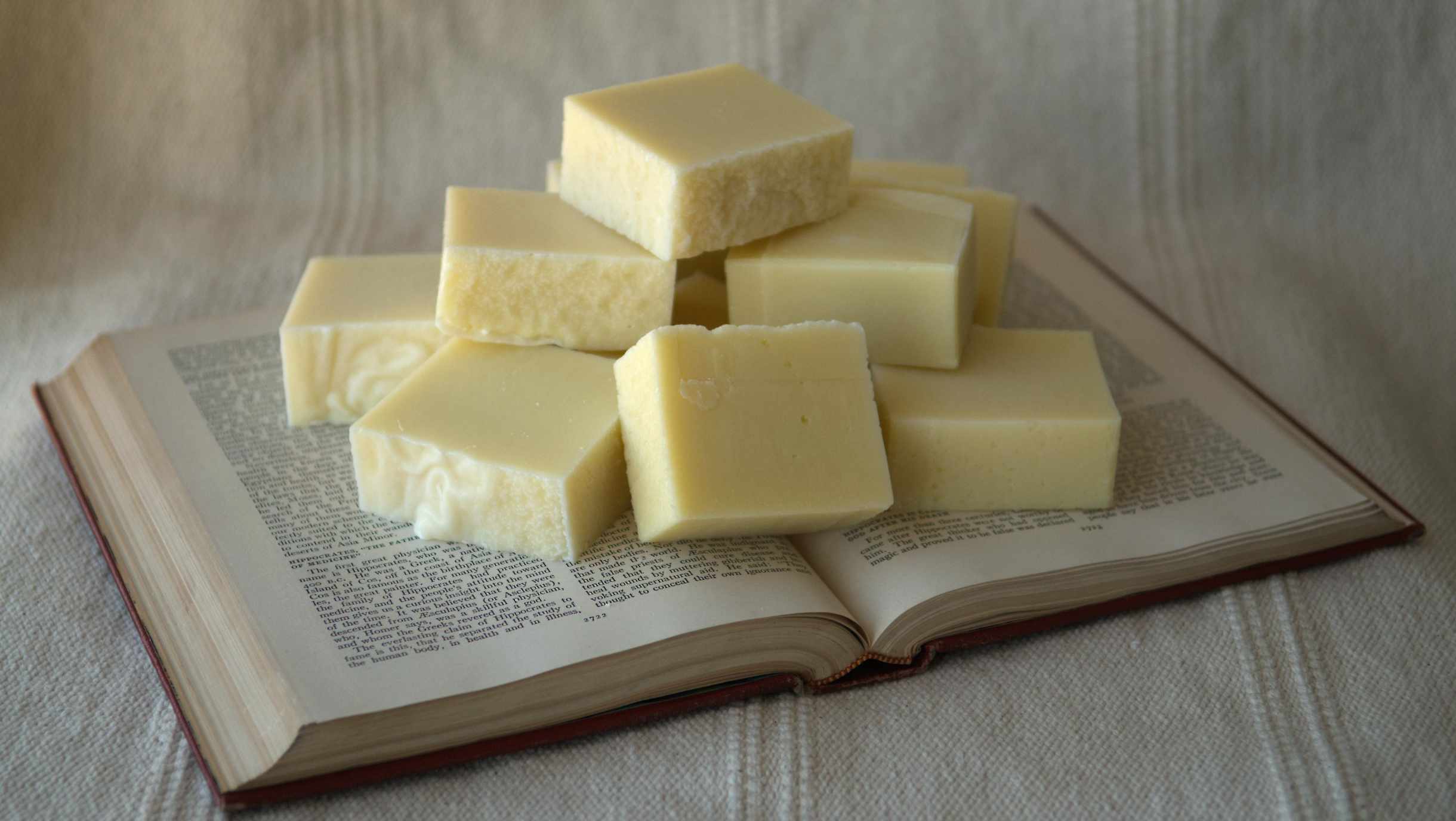

Glossary of Soapmaking Terms

Seasoned soapers and beginners alike should use correct terminology and Seasoned soapers and beginners alike should use the correct terminology and acronyms to communicate their messages clearly and to understand information correctly.

If you are new to soapmaking, it is essential to know and use correct terminology when embarking on a new soapmaking adventure.

Below is the vocabulary of the most common terms used by soapers at all levels.

Additive

An optional ingredient that is not an integral component of the soap itself. Lye, water, and oils/fats are the mandatory constituents of a soap recipe. Additives modify the soap by giving it fragrance, color, exfoliating properties, moisturizers, etc. These ingredients are added to your recipe at a light trace.

Aromatic Oils (Fragrance Oils)

Oils made of synthetic aromatic chemicals and carrier oils such as mineral or olive oils.

Base Oils (Fixed Oils)

Non-volatile oils that can withstand high temperatures without evaporating. Olive, vegetable, palm, and coconut oil are fixed oils. Fixed oils are also called Base Oils.

Caustic

Any acidic or basic substance that is able to burn or damage organic tissue by chemical reaction. Lye is caustic.

Cold Process (CP)

Soapmaking process that does not involve heating of the mixture. The lye solution is added to the mixture of oils and melted fats while being stirred by hand or with an immersion blender. Additives may be introduced to the recipe when the light trace is reached. The resulting soap batter is poured into molds and insulated to keep them warm for hardening. After 24-48 hours the soap becomes hard enough to be removed from the molds and sliced into bars.

Cold-processed soap bars must cure on drying racks for 4 to 6 weeks to complete saponification and to harden more by dehydration.

Curing

Aging of the soap made by cold process, to complete saponification and to solidify the soap by dehydration. Curing begins when the soap is removed from the molds, cut into bars, and placed onto drying racks. Curing usually takes 4 to 6 weeks. Curing produces a mild and solid bar that lathers very well and lasts a long time.

Discount

Reduction of the amount of a particular ingredient in saponification reaction. Discounts are usually shown in percentages.

A Lye discount is used to reduce the amount of lye required to saponify all of the oils and fats in the recipe. Discounting lye results in using up all of the lye and having some extra oils left in the soap. Lye is usually discounted at 3-10%.

Water discount is cutting back on the safe amount of water to speed up the solidification of the soap while it’s being cured. A safe amount of water is 36-38% of the total amount of oils and fats used in the recipe. This amount of water is easiest to work with as it gives you enough time to pour the soap into the molds after it has reached the trace. Be careful discounting water. Too little water speeds up saponification and may cause your soap to seize in the mixing bowl. Discounting water below 30% is not recommended.

Discounting certain ingredients also allows the addition of excess oils and other additives.

Essential Oils (EO)

Oils with natural scents extracted from plants. These oils may be added to soaps to create scented soaps.

False Trace

Thickening of the soap batter to a consistency that resembles Trace. False trace may happen when hard fats, such as tallow, are used in a soap recipe. The soap batter will thicken faster because the hard fats start solidifying at room temperature.

False trace should be avoided as you soap may produce pockets of lye that will be harsh on the skin.

To prevent false trace from happening, keep your soap batter above the melting temperatures of your hard fats.

Fixed Oils (Base Oils)

Non-volatile oils that can withstand high temperatures without evaporating. Olive, vegetable, palm, and coconut oil are fixed oils. Fixed oils are also called Base Oils.

Flashpoint

The minimum temperature at which a volatile liquid vaporizes to form an ignitable vapor. They will burn only in the presence of an ignition source and may stop burning when the ignition source is removed.

Flashpoint is used to determine when to add essential oils and fragrance oils to the soap. If the oil is added to the soap at a temperature that is higher than the oil’s flash point, the oil will evaporate and the soap won’t have the fragrance.

Typically, Fragrance oils have higher flash points than essential oils.

Fragrance Oils (FO)

Oils made of synthetic aromatic chemicals and carrier oils such as mineral or olive oils. Fragrance oils are sometimes called Aromatic Oils.

Gel Phase

An early stage of soap curing when soap becomes shiny and translucent. Not all soap batters undergo the gel phase. Gel Phase is also referred to as Gel Stage.

Hot Process Soap

Soapmaking method that requires external heat to speed up saponification and avoid curing. Heat is added to the soap batter after it reaches the trace. The soap batter is left to simmer for one-to-several hours. While simmering, saponification is reached, the gel phase is complete, and water is evaporated. The soap is removed from a heat source. Additives may be mixed in. The hot soap batter is poured into molds. The soap is solidified within a few hours, it can be cut into bars, and used immediately.

Hot-processed soap does not require curing.

Not all essential oils may be added to HP soap as their flash point may be lower than the hot soap batter, and the essential oils may evaporate.

Hot-processed soap does not have the same texture and looks like cold-processed soap.

Lye-Heavy Soap

Soap that contains excess lye. Lye and fatty acids react in certain proportions defined by SAP values. Too much lye in the recipe causes unreacted lye that is present in the soap. Lye-heavy soap is typically a result of a mistake, and it is not used for skin as it causes irritation. Sometimes, lye-heavy soap is made specifically as a cleaner or a detergent.

Saponification Value (Saponification Number, SAP Number, SAP Value)

The amount of lye (sodium hydroxide or potassium hydroxide) that is needed to saponify one gram of oil or fat. The saponification value is a characteristic of oils and fats. Each type of oil or fat has its specific saponification value.

Saponification values are important to know in order to balance the amounts of lye and oil/fat in a saponification reaction.

Saponification values of oils are different for the types of base that you are using, sodium hydroxide or potassium hydroxide.

Seize

Condition of soap batter when it rapidly solidifies in the mixing bowl and becomes too thick to pour into molds.

Seizing may be caused by too little water in the recipe, too much fats containing palmitic or stearic acids, waxes, and some essential or fragrance oils.

Soap Batter

Final mixture of the soap recipe when all main ingredients (lye, water, fats/oils) are mixed. Soap batter is stirred or mixed with a hand blender until it reaches the trace. Essential oils and other additives are mixed in at the trace. Then, the soap batter is poured into the molds.

Soap-on-a-Stick

Soap-on-a-stick is a colloquial term for soap seizing.

Syndet Bar

Syndet stands for “Synthetic Detergent.” Syndet bar is made of detergents synthesized from fats, oils, and petroleum products. Syndet bars are made by processes other than saponification. Although they look like soap, and they are called soap colloquially, they are not soap bars.

Superfatting

Creating excess oils/fats that remain unreacted in saponification.

Superfatting has three main purposes:

1. It gives you a margin of error making sure that all lye is saponified.

2. Produces moisturizing soap as extra oils serve as skin moisturizers.

3. Produces softer soaps and more lather.

Superfatting is achieved in two ways:

1. Lye discount.

2. Calculating the amount of lye to completely saponify oils/fats, and then adding more oils/fats.

Superfatting should be closely monitored as too much residual oil may cause unpleasant and greasy soap.

Trace

The stage in soap mixing when most of the oils and fats have successfully reacted with lye (saponified) and turned into soap. Trace can be identified by the pudding-like consistency of the soap batter.

If you drizzle some of the soap on the surface of the mixture, it leaves back a trail that will slowly sink back into the mixture.

Trace should not be confused with false trace. The term can be found in the Glossary of Soapmaking Terms.

Volcano Effect

The volcano effect happens when water is poured into lye (instead of lye into water) when mixing lye and water. This happens because of the exothermic reaction that causes pressure build-up underneath the lye when water is poured onto the lye. When enough pressure is built hot lye/water mixture explodes like a volcano.

To avoid the volcano effect, never pour water into the lye. Pour the lye into the water instead.